Decision makers don’t buy drone services because drones are interesting. They buy them because drones solve expensive problems faster, safer, and with better documentation than traditional methods.

Two of the most common “quiet budget leaks” in commercial and industrial operations are:

- Uncertain stockpile quantities (inventory accuracy, shrink, vendor disputes, production planning)

- Hard-to-pinpoint roof moisture and leakage (reactive repairs, interior damage, warranty disputes, wasted contractor hours)

Thermal-capable drones address both—when deployed correctly. This article breaks down what thermal drones actually measure, where they create measurable business value, what conditions must be present for reliable results, and what a professional deliverable should look like for both stockpile reporting and roof diagnostics.

What Thermal Drones Measure (and What They Don’t)

Thermal cameras don’t “see water.” They measure infrared radiation and translate it into a surface temperature map.

That temperature map can reveal patterns that correlate strongly with:

- Moisture retention (wet materials often heat/cool differently than dry materials)

- Thermal bridging and insulation voids

- Air leakage pathways

- Heat loss

- Subsurface anomalies that create temperature differences on the surface

But thermal work is not magic. Reliable interpretation depends on:

- Environmental conditions (sun, wind, ambient temp)

- Timing (day vs night, post-sunload, post-rain)

- Material properties (emissivity, reflectivity, density, moisture content)

- Proper calibration and workflow (radiometric capture, consistent settings, QA checks)

Thermal drones provide strong evidence—but your process has to be designed so the evidence is meaningful.

Part 1: Thermal Drones and Stockpile Reporting—Where “Accurate” Gets More Complicated

Stockpile reporting is usually framed as a geometry problem: “How much volume is there?” But volume is only half the story. In many real-world operations, the pain comes from inconsistencies like:

- Wet material vs dry material (affects weight conversion assumptions)

- Mixed materials in one yard

- Frozen crust or compacted layers

- Hot spots or combustion risk (coal, mulch, compost)

- Shrink and loss that can’t be explained confidently

Where Thermal Adds Value to Stockpile Work

Thermal imaging can enhance stockpile reporting by adding a condition layer to your measurement workflow:

1) Identifying moisture variation zones

Moisture changes how material behaves operationally and how it converts from volume to tonnage. Thermal can help flag:

- areas that retain moisture longer

- runoff patterns

- pooling near berms and containment areas

That matters when:

- you’re converting volume to weight using assumed densities

- you’re troubleshooting variability in product performance

- you’re trying to explain “why this month’s numbers don’t reconcile”

2) Detecting heat anomalies (safety + risk management)

Some materials can self-heat or develop hot spots (notably organic bulk piles like mulch/compost, and certain coal or waste environments). A thermal survey can identify abnormal heat patterns early, supporting:

- safety protocols

- remediation planning

- documentation for internal reporting

3) Creating clearer documentation for disputes

When disagreements happen—vendor, customer, internal—thermal imagery adds context. It can show that “this is not the same pile condition as last time,” or that parts of the yard were affected by weather exposure differently.

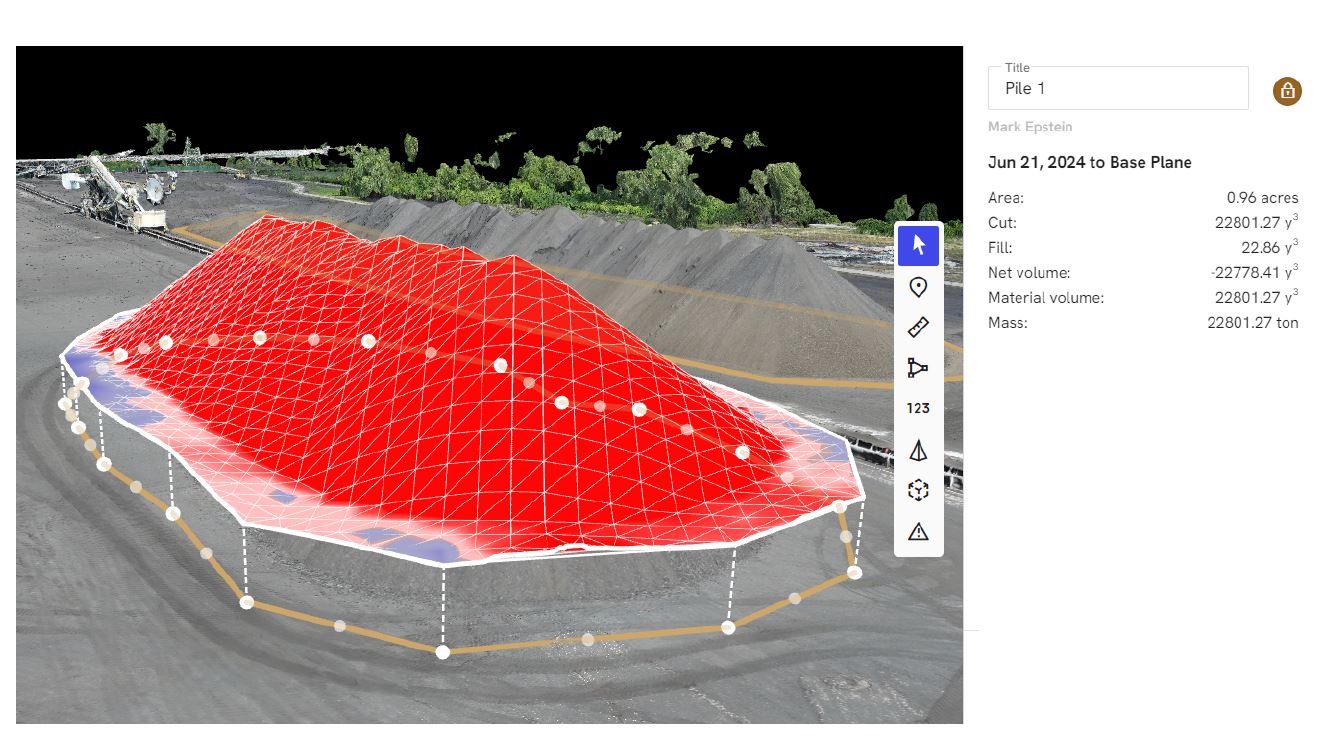

Important Reality Check: Thermal Does Not Replace Volume Measurement

Thermal is not your volume measurement tool. For stockpile quantities, your best accuracy usually comes from:

- LiDAR (best for complex environments and repeatability)

- Photogrammetry (excellent in the right conditions)

- Solid georeferencing and repeatable base-surface rules

Thermal strengthens the interpretation layer: moisture, heat, condition, risk.

Part 2: Thermal Drones and Roof Leakage—From “Somewhere Over There” to Actionable Targets

Commercial roofs can fail slowly and invisibly. The most expensive roof leaks aren’t always the dramatic ones—they’re the slow moisture intrusions that:

- saturate insulation

- reduce R-value

- spread laterally under membranes

- create mold risk

- damage tenant spaces

- turn minor repairs into major replacements

Thermal drone inspections can accelerate leak investigation by highlighting areas where wet insulation behaves differently than dry insulation—especially when your timing and conditions are correct.

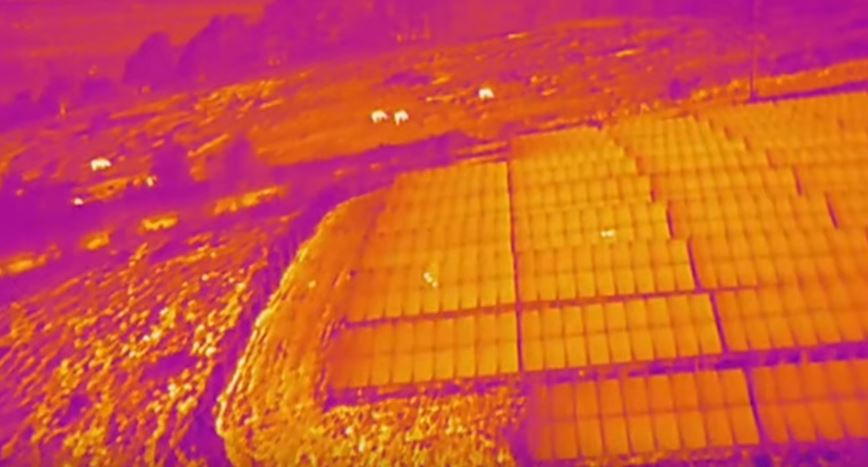

How Thermal Finds Likely Moisture Intrusion Areas

A common approach is to capture thermal when there’s a meaningful temperature differential between wet and dry areas.

Often (but not always), that’s:

- after solar loading (late afternoon into evening), as wet areas hold heat longer

- or pre-dawn in some climates, depending on roof type and conditions

When the roof has been heated by the sun, wet insulation may cool more slowly. That difference can show up as thermal anomalies, giving contractors a prioritized map of “start here.”

What Thermal Drone Roof Inspections Do Best

Thermal drone work is especially valuable for:

- Large, flat commercial roofs where walking the entire surface is slow and costly

- Facilities where access is limited or safety concerns exist

- Pre-repair targeting to reduce destructive test cuts

- Documentation for warranty conversations and maintenance planning

- Baseline scans to track change over time after repairs

Conditions That Make or Break Accuracy

Roof thermal results depend heavily on environmental and operational variables:

- Wind can flatten thermal contrast

- Rain timing matters (wet surface vs wet insulation are not the same)

- HVAC exhausts, vents, and equipment create expected hot/cold zones

- Reflective membranes can complicate interpretation

- Shaded areas behave differently than sun-exposed areas

A professional provider doesn’t just hand over colorful images. They annotate likely moisture areas, flag confounding factors, and provide a plan view that contractors can actually use.

What a Decision Maker Should Demand in Deliverables

Whether you’re measuring stockpile conditions or roof anomalies, insist on deliverables that work for real stakeholders:

For roof diagnostics:

- A roof plan view with annotated anomalies

- Visible + thermal paired images (same viewpoint when possible)

- Notes on environmental conditions and timing

- A clear “limitations” section (vents, HVAC, shade zones, reflective surfaces)

- Optional: orthomosaic overlays for facility management records

For stockpile documentation:

- Site map with labeled areas (piles, zones, traffic patterns)

- Thermal maps showing moisture/heat zones of interest

- If paired with volume work: consistent pile boundaries and date-stamped reports

- Export formats your team can use (PDF for leadership, images for contractors, spreadsheets for records)

A Smart Strategy: Combine Sensors for “Measurement + Meaning”

For many organizations, the best approach is not choosing one sensor. It’s combining them:

- LiDAR/photogrammetry for accurate volume and change tracking

- Thermal for moisture/heat context and risk insight

- High-resolution visual imagery for documentation, marketing, and stakeholder communication

That combination produces something decision makers love: fewer surprises, cleaner reporting, and stronger documentation when questions arise.

Why St. Louis Aerial Photography Is Built for Industrial Accuracy and Marketing-Grade Content

At St. Louis Aerial Photography, we don’t treat thermal drone work as a novelty. We treat it as part of a professional production and reporting pipeline—designed to produce actionable results for operations, facilities, and leadership.

We are a full-service professional commercial photography and video production company with the right equipment and creative crew service experience for successful image acquisition. We offer full-service studio and location video and photography, along with editing and post-production, supported by licensed drone professionals. St. Louis Aerial Photography can customize your productions for diverse media requirements, and repurposing your photography and video branding to gain more traction is one of our specialties.

We’re well-versed in all file types, media styles, and the software ecosystems businesses and agencies rely on. We also use the latest Artificial Intelligence across our media services—supporting faster turnarounds, smarter workflows, and consistent deliverables.

Our private studio lighting and visual setup is ideal for small productions and interview scenes, and our studio is large enough to incorporate props to round out your set. We support every aspect of your production—from building a private, custom interview studio to supplying professional sound and camera operators, and providing the right equipment—ensuring your next video production is seamless and successful. And when conditions require it, we can fly specialized drones indoors.

As a full-service video and photography production corporation since 1982, St. Louis Aerial Photography has worked with many businesses, marketing firms, and creative agencies across the St. Louis area—delivering the kind of reliable capture, documentation, and storytelling that decision makers depend on.

If you want stockpile reporting with better context, roof leak targeting that reduces wasted repair time, and visuals that elevate your brand at the same time, thermal drones can deliver—and we can execute the entire process end-to-end.