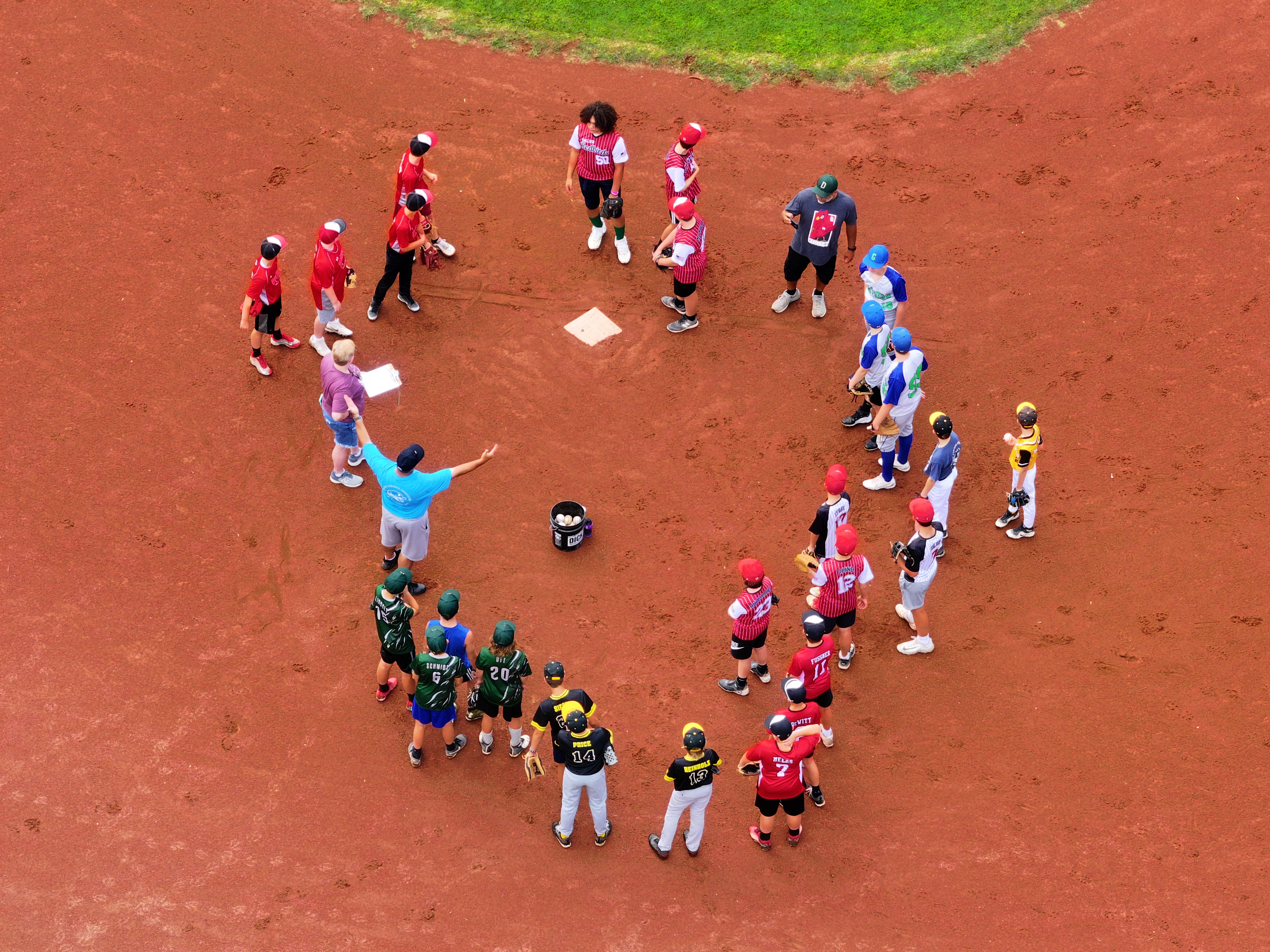

B-roll is the connective tissue of effective marketing video—those quick, high-impact visuals that set context, elevate perceived production value, and keep viewers watching. And in St. Louis, drone b-roll is often the fastest way to make a brand look bigger, more established, and more credible: a smooth reveal of a headquarters, a sweeping view of a jobsite, an overhead of a campus, a cinematic push-in on a venue, or a top-down of a warehouse operation.

But decision makers are right to ask the hard questions:

- How do we get cinematic aerial b-roll without blowing the budget?

- What actually drives cost—flight time, pre-pro, edits, permits, travel, revisions?

- How do we avoid unusable footage, compliance headaches, and deliverables that don’t fit our marketing pipeline?

This article is a practical guide to getting economical, repeatable, high-quality drone b-roll that plugs directly into brand campaigns, websites, recruiting, proposals, social media, and sales enablement.

Why drone b-roll is one of the highest-ROI production upgrades

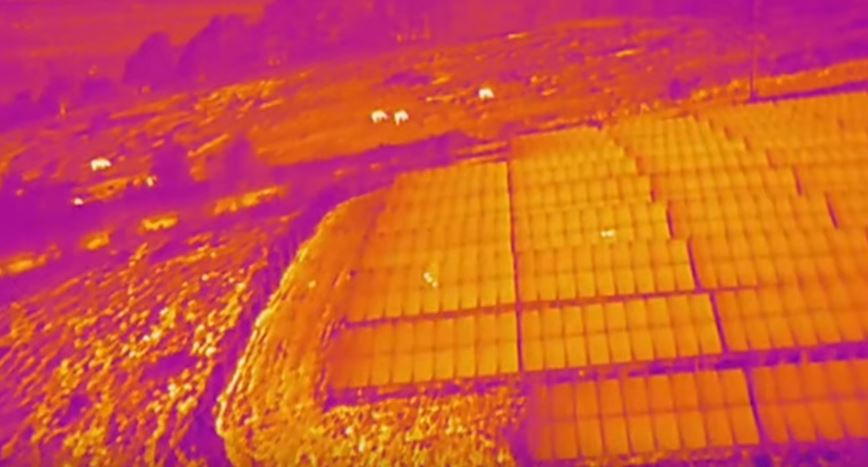

If your team is producing any of the following—brand videos, recruiting, testimonials, events, construction updates, real estate/commercial property, facility tours, or social campaigns—drone b-roll can deliver outsized value because it:

- Creates instant context (where you are, what you do, scale of operations)

- Improves credibility (polished visuals signal professionalism and stability)

- Increases reusability (one aerial session can feed dozens of deliverables)

- Boosts editing efficiency (b-roll hides jump cuts, bridges scenes, supports voiceover)

- Upgrades your brand “look” quickly compared to building sets or renting locations

The key is to treat drone b-roll like a strategic asset library, not a one-off novelty shot.

What “economical” really means in drone b-roll production

Economical is not “cheap.” Economical means:

- Planned shots that you will actually use

- Efficient capture that minimizes setup, downtime, and reshoots

- Deliverables organized for your marketing workflow

- Compliance handled cleanly so the footage is publishable

- A visual style consistent with your brand

The fastest way to waste money is to “go get some drone footage” without a plan. The fastest way to save money is to capture the right shots once—then repurpose them across campaigns.

The b-roll brief: the single best cost-control tool

Before a drone ever takes off, you should have a short, decision-maker-friendly brief that answers:

- Who is this for? (prospects, recruits, investors, internal stakeholders)

- Where will it live? (homepage hero, YouTube, LinkedIn, paid ads, trade show, proposals)

- What is the message? (scale, safety, craftsmanship, innovation, hospitality, trust)

- What is the visual tone? (premium/cinematic, clean/corporate, energetic/social)

- What are the non-negotiables? (logo signage, key buildings, people, equipment, time of day)

A good drone b-roll plan is not long. It’s simply specific.

Example: a practical “shot list” that stays economical

For many organizations, a single efficient session can capture:

- Establishing: wide exterior, approach, orbit, overhead

- Detail: signage, entrances, unique architecture, loading bays, fleet

- Operations: vehicles moving, cranes, equipment, foot traffic, workflow patterns

- Environment: proximity to highways/landmarks, neighborhood context, campus layout

- “Hero moments”: sunrise/sunset angles, dramatic reveals, seasonal looks

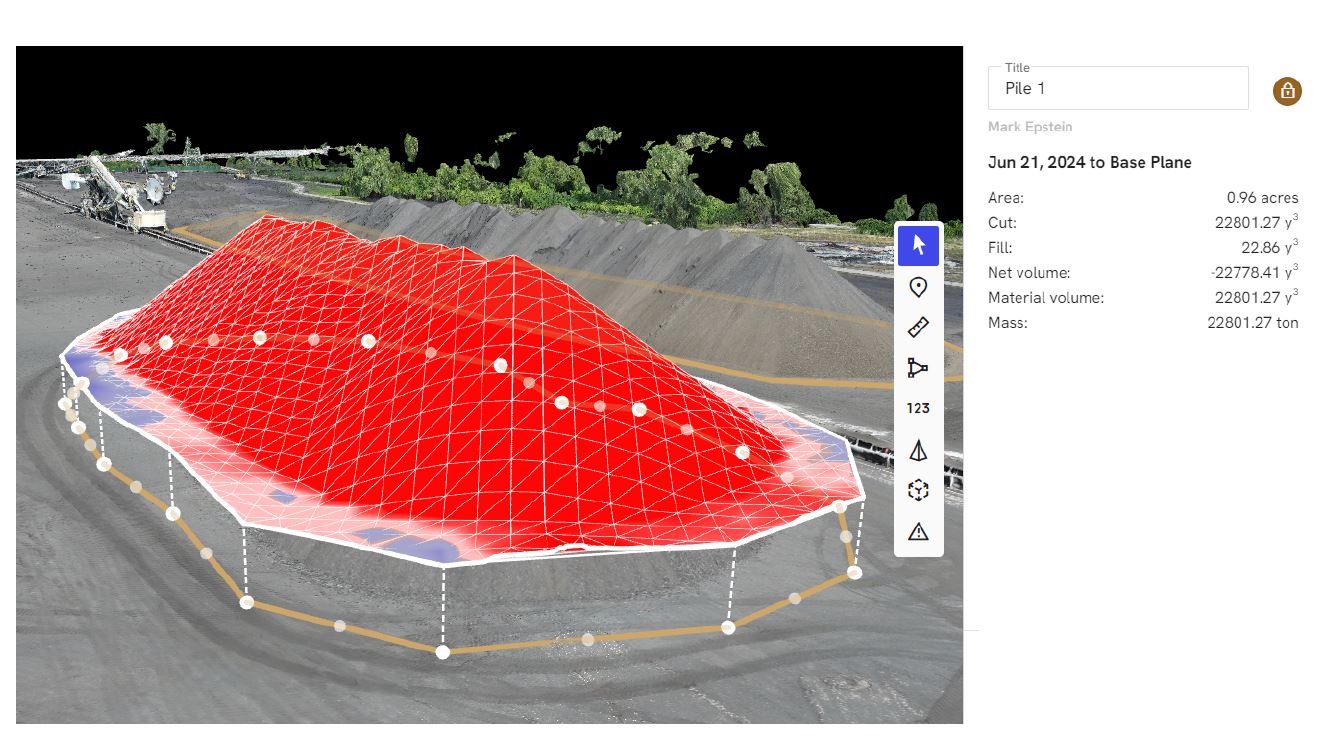

- Safety/scale: top-down perspectives that communicate organization and capacity

When the list is intentional, the session stays tight—and the edit becomes faster.

Scheduling: time of day and weather are budget multipliers

Economical drone b-roll depends heavily on conditions. Two factors can make average footage look expensive (or expensive footage look average):

1) Light

- Early morning / late afternoon creates dimension, contrast, and texture.

- Midday sun is harsher—often workable, but less cinematic without additional planning.

2) Wind

- Stable conditions yield smoother motion, cleaner framing, and fewer retakes.

- High wind increases capture time and risk of unusable clips.

Smart scheduling reduces total time on site and increases usable footage—two direct drivers of cost.

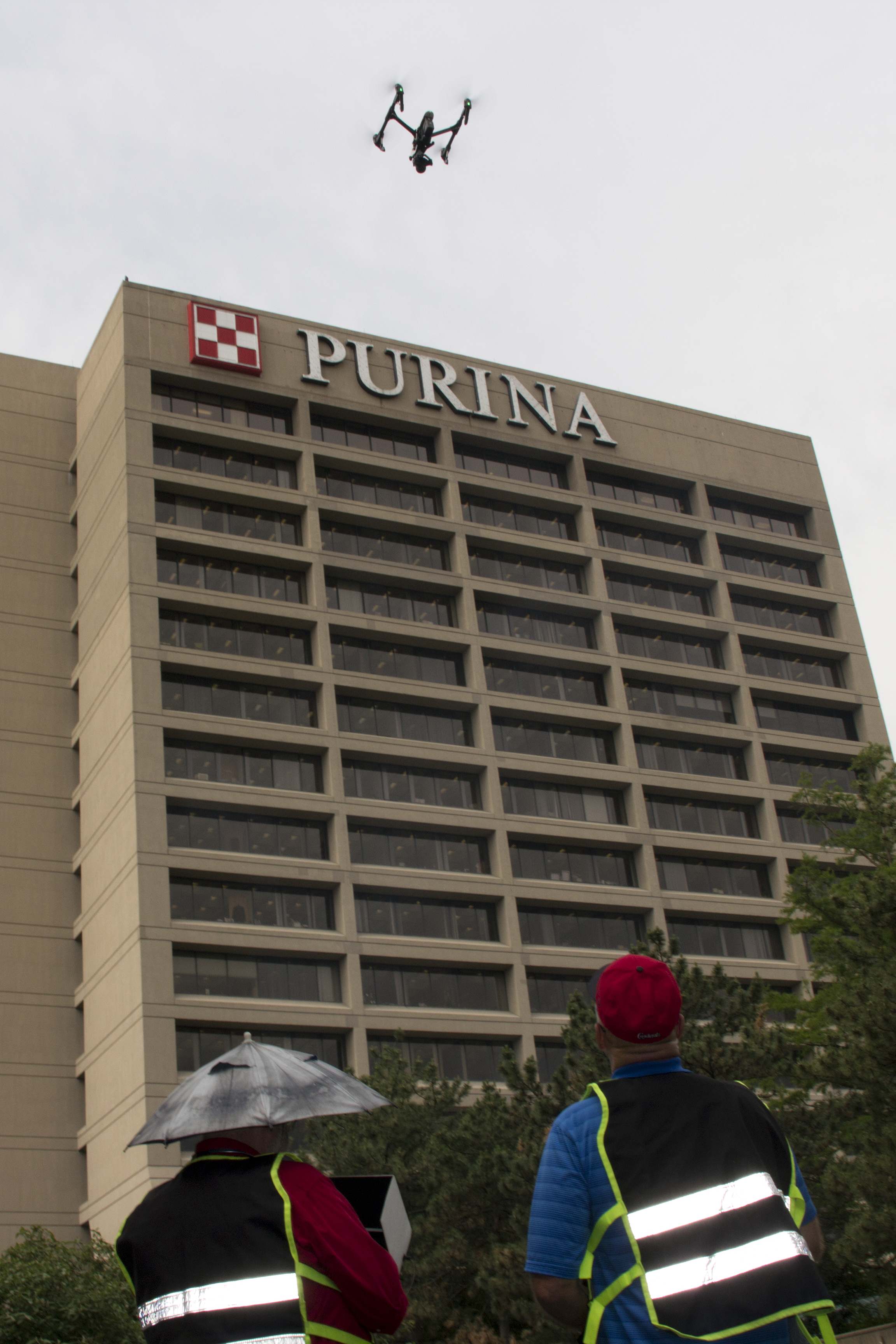

Compliance and risk: the hidden cost center you don’t want to own

Decision makers usually don’t want to be in the business of drone regulations, permissions, or risk mitigation. They just want the footage to be lawful, safe, and publishable.

A professional drone b-roll workflow includes:

- Licensed operations and flight planning

- Location considerations (people, traffic, structures, restricted airspace)

- Communication on-site (safety perimeter, coordination with operations teams)

- A capture plan that avoids “we’ll fix it later” problems

Economical means fewer surprises, fewer delays, and no “we can’t use this footage” moment after the shoot.

Capture strategy: how to get more usable b-roll in less time

Experienced aerial production crews focus on usable variety. That means:

- Multiple angles per key subject (wide, medium, detail)

- Mix of motion types (reveal, lateral slide, push-in, rise, orbit, top-down)

- Clean starts and stops for edit-friendly clips

- Coverage continuity so editors can build sequences, not just isolated shots

This is where many “budget” drone shoots fail: they return with pretty clips that don’t cut together, don’t match brand tone, or don’t support messaging.

A controlled, repeatable approach produces an asset library your team can reuse for months.

Deliverables that make marketing easier, not harder

Economical drone b-roll isn’t only about the shoot—it’s about how the footage is delivered.

A professional deliverable package should be designed around your marketing stack and internal team:

- Clearly organized folders and naming conventions

- Versions for common uses (web, social, broadcast, vertical formats)

- Footage that matches the rest of your campaign (color, style, frame rates)

- Optional selects/reel for fast approvals

When the post workflow is efficient, your internal cost drops too—less time hunting for clips, less re-exporting, fewer re-edits.

AI and modern post: where it saves money and where it doesn’t

Used correctly, AI tools can help reduce cost and increase speed without compromising quality. Examples of smart AI-assisted efficiencies include:

- Faster logging, transcription, and selects (when integrating interviews + b-roll)

- Noise reduction and audio cleanup for mixed productions

- Captioning and versioning for social deliverables

- Asset tagging and searchability for large footage libraries

- Streamlined resizing and reframing for vertical content

What AI does not replace is capture fundamentals: strong composition, stable motion, correct exposure, and intentional shot design. Economical outcomes come from getting the capture right—then using AI to accelerate the finishing and repurposing.

How to build a “b-roll bank” for ongoing savings

If you create content regularly, the best economics come from building a repeatable “bank” of aerial visuals that support multiple campaigns.

A practical approach:

- Schedule drone b-roll capture quarterly or seasonally

- Update visuals after major facility changes, new signage, renovations, or fleet updates

- Capture during key operational moments (busy periods, events, milestones)

- Maintain a consistent brand look so new footage integrates with old

This turns drone b-roll into a compounding asset—each shoot reduces the need for future shoots and improves campaign agility.

Common pitfalls that inflate costs (and how to avoid them)

- No plan, no shot list → results in extra time and low usable yield

- Ignoring light and wind → footage looks flat or unstable

- Unclear deliverables → post-production churn and revision loops

- Not coordinating with site operations → delays, safety issues, missed moments

- Capturing “cool shots” instead of “marketing shots” → footage doesn’t serve objectives

Economical drone b-roll is a discipline: plan, capture efficiently, deliver cleanly.

Why St Louis Aerial Photographers for economical St. Louis b-roll

At the end of the day, you’re not hiring a drone—you’re hiring a production partner who can reliably deliver usable, on-brand, compliant aerial b-roll that drops into your marketing pipeline.

As a full-service video and photography production corporation since 1982, St Louis Aerial Photographers is a full-service professional commercial photography and video production company with the right equipment and creative crew service experience for successful image acquisition. We offer full-service studio and location video and photography, as well as editing, post-production, and licensed drone services. St Louis Aerial Photographers can customize your productions for diverse types of media requirements. Repurposing your photography and video branding to gain more traction is another specialty.

We are well-versed in all file types and styles of media and accompanying software, and we use the latest in Artificial Intelligence for all our media services. Our private studio lighting and visual setup is perfect for small productions and interview scenes, and our studio is large enough to incorporate props to round out your set. We support every aspect of your production—from setting up a private, custom interview studio to supplying professional sound and camera operators, as well as providing the right equipment—ensuring your next video production is seamless and successful. We can fly our specialized drones indoors.

If your goal is economical drone b-roll that still looks premium, the formula is simple: intentional planning, efficient capture, experienced post, and deliverables built for marketing. That’s exactly how we work.